ECOPOT

ECOPOT aims to develop a machine to transform organic waste like dry leaves and branches into biodegradable plant pots. This involves adding a plant-based binder to create a sturdy container structure. Our goal is to create an innovative machine enabling local nurseries to replace single-use blow-molded plastic pots with biodegradable ones produced on-site.

Ecopot consists of three main stages. Firstly, the crushing and mixing stage operates independently, followed by extrusion and molding, and finally, the carousel. Although the latter are powered by different mechanisms, they function simultaneously.

Stage 1: The container is positioned on the left side of the machine for the crushing and mixing process. Firstly, the blade is placed in the housing, then the leaves are added to the container, initiating the crushing process. Once the leaves are crushed, the housing moves upward, the crushing accessory is exchanged for the harp, and the pre-prepared vegetable binder is added to begin the mixing process.

Stage 2: Once the mixture is homogenized, the container is manually removed and transferred to the right side of the machine for extrusion using a plunger. After extruding the required amount of dough, two blades are activated to cut the dough, dropping it into the female mold below. Stages 2 and 3 now operate simultaneously.

When the dough falls into the first mold, the turntable moves it to the molding station. This rotational movement positions the filled female mold under the male mold, which, upon descent, applies pressure to mold the pot. The turntable then rotates again, leaving the mold with the pot ready for extraction.

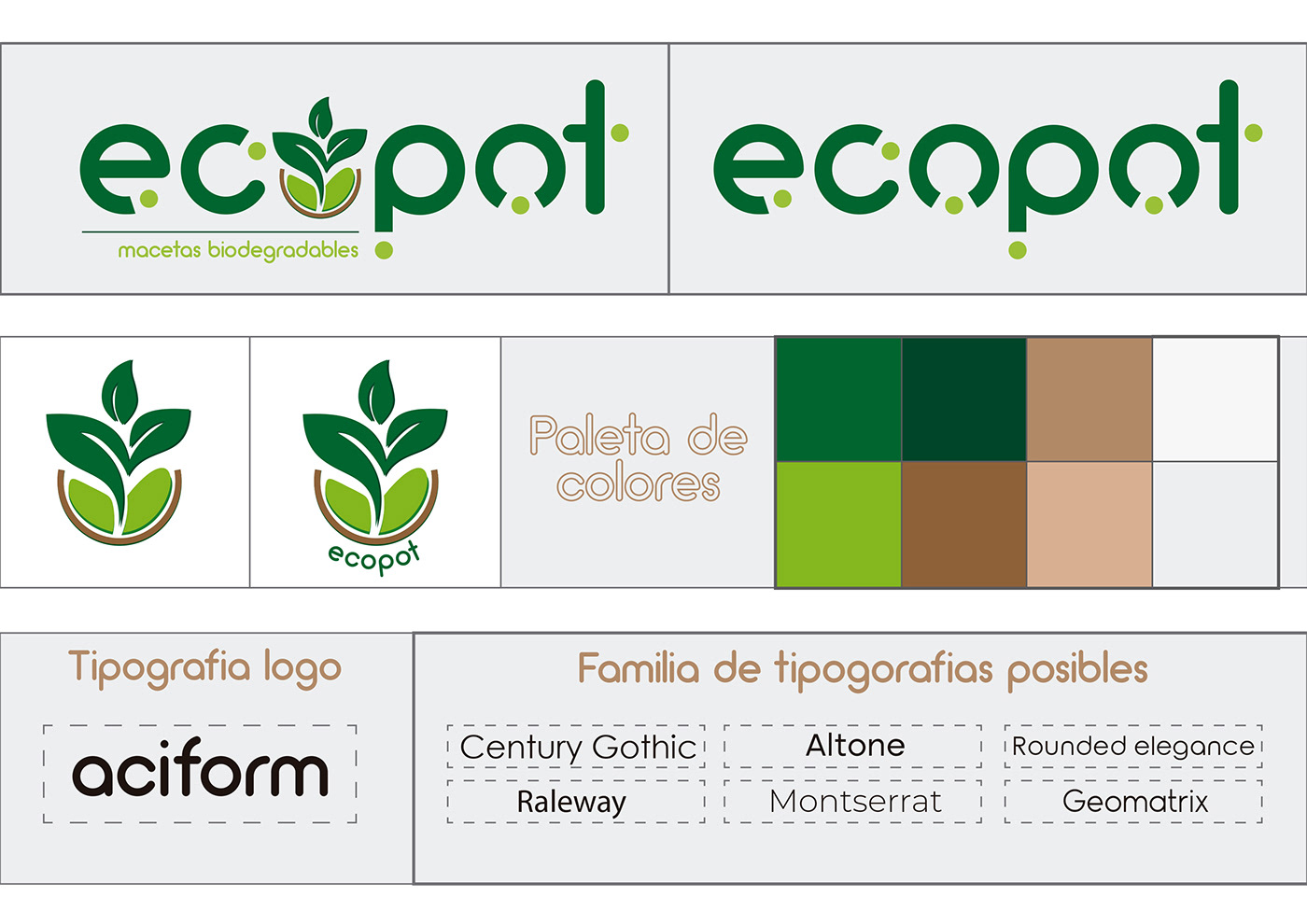

Brand Identity